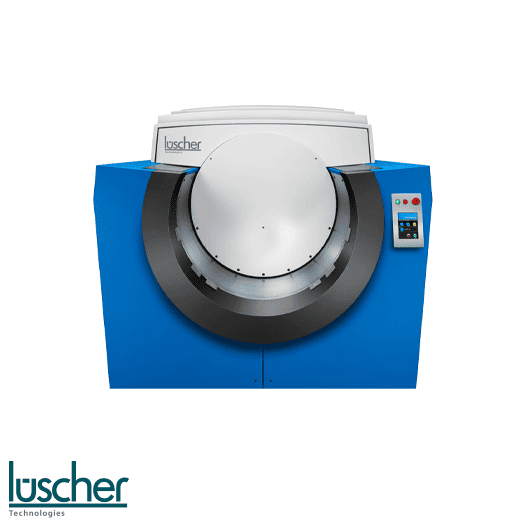

XPose! Advantages of FlexLine!

- OPTIONAL FLEXTREME! OPTICS FOR MULTIPLE RESOLUTIONS UP TO 5'080 DPI

- NO LOSS OF SPEED WITH PLATE THICKNESS UP TO 6.35 MM

- EASY LOADING AND UNLOADING

- NOT DEPENDENT ON SPECIFIC FORMATS

- ALSO SUITABLE FOR TYPE / DRY OFFSET MOLDS

- FULL HD FLEXO INCLUDED

- X!MASK SOFTWARE FOR SURFACE SCANNING

<Lüscher Laser Diode Technology

Fiber-coupled laser diodes operate in the 980 nm range and is characterized by an ultra-long service life of up to +15'000 exposure hours. They are completely maintenance-free and do not require an active cooling system.

Fully Automatic and Continuous Calibration

XPose! Flex Line features unique Continuous Calibration Technology (CCT). The performance of each laser is monitored during exposure and automatically adjusted if necessary. Thus, costly, inappropriate risks can be eliminated.

Lowmost Energy Consumption

Lüscher's patented laser diode technology, It reduces costs and provides lower cost of ownership by ensuring minimum power usage of 2 kW / 2.5 kW. This promotes environmentally friendly production for customers.

fleXtreme! Optics for Multiple Resolutions

Optional fleXtreme! The optic is a product developed in-house by Lüscher and allows the desired resolution to be selected. The migration is completely automatic and tailored to the requirements. This means that every job can be displayed at any resolution.

Full HD Flexo Included

Standard equipment includes a dual optical system. XPose! Flex Line allows the user to make full HD exposures at 5'080 dpi or standard resolution 2'540 dpi with a simple click of a button - XPose! Flex Line makes things easier for you. Other resolutions are also available upon special request; For example, 2'400/4'800 dpi as dual optics or 4'000 dpi as single optics are optionally available at no extra cost.

X!Mask for Superior Quality

X!Mask Software, developed by Lüscher Technologies AG, automatically recognizes surfaces or small dots or lines. It allows higher density values in solid areas by creating structures or micro cells on surfaces fully automatically. The operator is free to configure the shape and size of the microcells. Highlight points and hairlines can be defined by the software and automatically assigned to broad shoulders. The software is RIP independent and runs fully automatically on the output computer.

Easiest Plate Usage

The unique patented combination of inner and outer drum technology allows for easy and fast operation. Since plates of all sizes and thicknesses are static, there is no need for tension rails or time-consuming taping of plates onto the drum. Even 50 x 80 inch printing plates can be easily loaded and unloaded by the operator.

Technical specifications

|