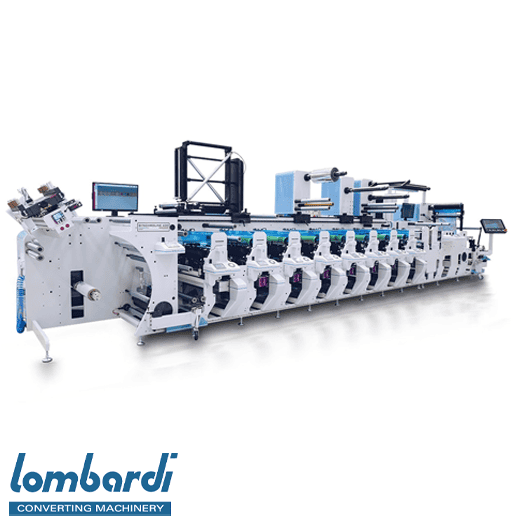

"Tag the Future" with Synchroline means looking beyond current limitations and embracing the limitless potential of print. With this revolutionary machine, every project becomes an opportunity to explore new horizons in label and packaging production. Thanks to its versatility, Synchroline can print on a wide range of substrates including BOPP, PVC, PE, PET, paper, release paper, thermal paper, cardboard, laminates and many more.

Synchroline's advanced automation minimizes operator efforts, ensuring the highest quality in the flexographic process. With Synchroline, every step of production becomes more efficient and precise.

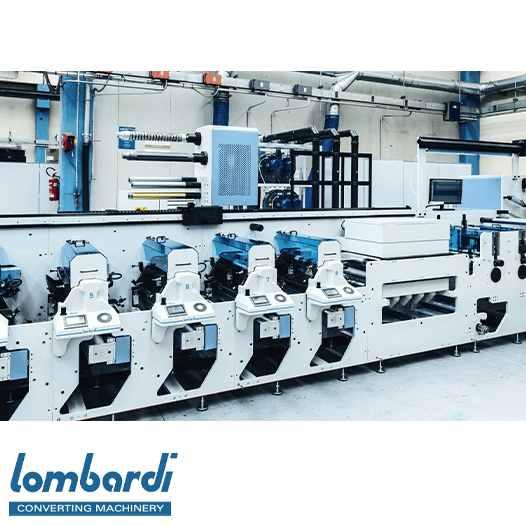

But Synchroline is much more than that: it is a fully modular inline flexography machine that can be adapted to meet specific production needs. From multi-layer units to hot foiling, screen printing to cold foiling and more, Synchroline offers a wide range of options to customize the printing process.

In short, Synchroline is a printing freedom machine. Every label that passes through Synchroline is a blank canvas ready for art and innovation. Label the Future with Synchroline means inspiring the world with your creativity and redefining what is possible in label and packaging production. Synchroline is an innovation that moves the printing industry forward, opening up new opportunities and enabling businesses to uniquely stand out in the market.

MAIN FEATURES

SYNCHROLINE A.B.S. Equipped with. printing unit:

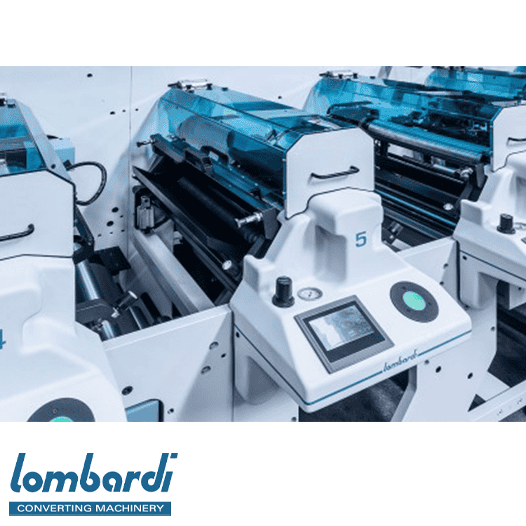

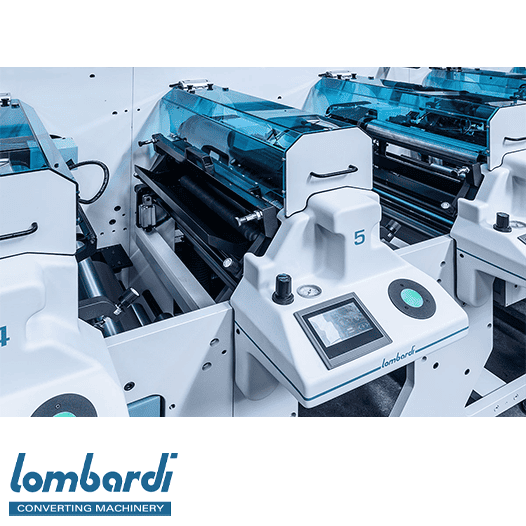

Hi-FiT system: An innovative system is used for printing rollers, which allows the immediate installation of rollers of different diameters without the need for adapters. In fact, printing rolls lie on a special algorithmically studied curve that can keep the printing pressure constant by varying the roll diameter.

Hi-FiX system: The plate cylinder is pneumatically clamped with a tapered piston, ensuring irreversibility of movement and minimizing movements and vibrations.

Hi-DynamiX system: The blade is pressed against the anilox roller by the pneumatic system, determining an automatically adaptive pressure dynamic to ensure the best ink distribution.

Hi-InX system: When the machine stops, the ink roller (anilox) is first removed to remove excess ink, then (after an adjustable time) the print roller is removed (an important operation when using non-UV inks).

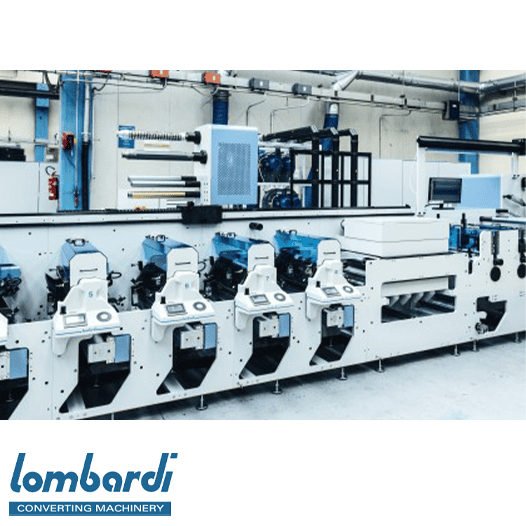

FRONT ELECTRONICS:

- Fully automatic electronic pre-registration system: minimum material waste, minimum loss of time, maximum precision.

- Fully automatic registration controls with parameterization system for perfect registration on expandable materials.

- Electronic tension control for perfect tensioning of different surfaces.

- Quality analysis system.

Technical Specifications