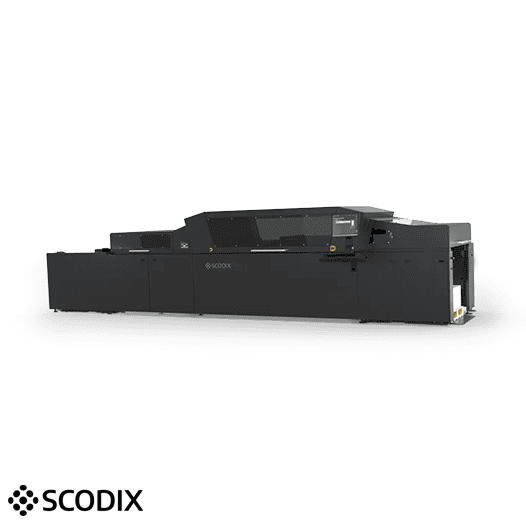

Digital Enhancement Press for the Packaging Market

The Scodix Ultra 5000 is a digital enhancement press designed for the high-end packaging market, offering exceptional performance for rigid box and folding carton applications. It is ideal for short run productions, increased SKUs, and new markets. This press enables packaging manufacturers to add value to brands, with the ability to print on thick papers and support pallet feeders and pallet stackers, meeting the core needs of a packaging print factory.

Scodix Ultra 5000 Applications

-

Scodix Sense™

-

Scodix Foil™

-

Scodix Metallic™

-

Scodix Glitter™

-

Scodix Spot™

Optional Applications:

-

Scodix VDE™

-

Scodix Cast&Cure™

-

Scodix Braille™

-

Scodix Crystal™

|

Technical Specifications |

|

|

Feature |

Description |

|

Scodix Technology |

Digital Print Enhancement with inline foil, based on Scodix PAS™ technology |

|

Foil Roll Width (Min-Max) |

50-500 mm/1.97-19.68 in |

|

Foil Roll Size (Max) |

Diameter: 30 cm/11.8 in; Length: 2,000 m/2187 yd, Core: 77 mm/3 in |

|

Number of Simultaneous Rolls |

Up to 4-rolls |

|

Resolution |

Up to 2,540 x 450 DPI |

|

Scodix RSP™ Technology |

4-CCD camera system, RSP™ (Rotate, Scale, Position) algorithm, automatic positioning, ±100 micron image to image registration |

|

Printing Area (Max L x W) |

504 x 748 mm / 19.8 x 29.4 in |

|

Substrates** |

Offset, plastics, laminated, coated/uncoated substrates |

|

Substrate Format (Min: Max-L x W) |

297 x 420 mm: 545 x 788 mm/11.7 x 16.5 in: 21.5 x 31 in |

|

Substrate Range |

135-675 gsm/6-30 points, up to 0.7 mm |

|

Compatibility* |

Offset, HP Indigo ElectroInk, Inkjet, Lamination, Toner |

|

Speed (Max) |

1,250 SPH |

|

Feeder/Stacker |

Pallet/Pallet |

|

Polymer* |

1-bottle, all Scodix polymers |

|

Polymer Layer Thickness |

From 5 up to 250 microns |

|

Polymer Switch |

Automatic |

|

Variable Data Enhancement (VDE) |

PDF, optimized PDF, barcode system included |

|

*Applications and compability are an outcome of the polymer chosen |

|

|

**Based on Scodix Recommended Substrate List (RML) for foil where surface tension should be within range of 36-44 dyne/cm |

|