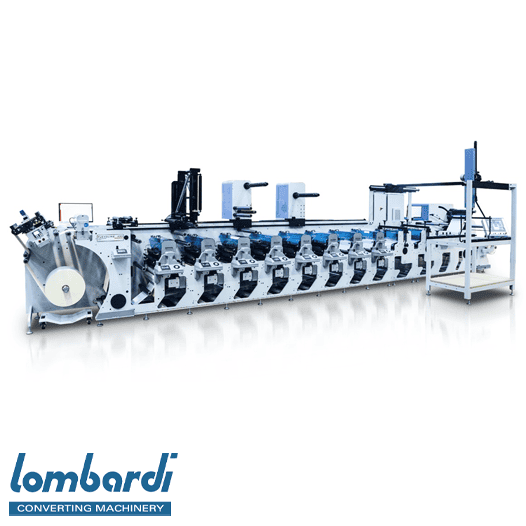

PRODUCT OVERVIEW

The Lombardi experience focuses on a high-tech narrow web machine for printers looking for high print quality with simple and fast job changeover.

The company placed great emphasis on these two aspects of flexographic printing: the quality of the images (which is now almost lost to offset printing) and the rapid changeover of printing rollers and ink rollers.

In light of this need, Flexoline offers advanced technological solutions that aim to provide perfect print recording at high speeds and ease of use.

MAIN FEATURES

FLEXOLINE A.B.S. Equipped with. printing unit

Hi-FiT system: An innovative system is used for printing rollers, which allows the immediate installation of rollers of different diameters without the need for adapters. In fact, printing rolls lie on a special algorithmically studied curve that can keep the printing pressure constant by varying the roll diameter.

Hi-FiX system: The plate cylinder is pneumatically clamped with a tapered piston, ensuring irreversibility of movement and minimizing movements and vibrations.

Hi-DynamiX system: The blade is pressed against the anilox roller by the pneumatic system, determining an automatically adaptive pressure dynamic to ensure the best ink distribution.

Hi-InX system: When the machine stops, the ink roller (anilox) is first removed to remove excess ink, then (after an adjustable time) the print roller is removed (an important operation when using non-UV inks).

FLEXOLINE offers the best solutions for a printing machine with the highest quality standard and ease of use, which we know are the main needs of label printers.

FLEXOLİN. PRESSURE IMPROVE YOU.

FOUR WINNING CONCEPTS OF THE FLEXOLINE PRINTING UNIT

- Hi-FiT system: The printing roller lies on a special curve that guarantees that the printing pressure remains constant for different roller diameters. No adapter needed.

- Hi-DynamiX system: The blade is pressed against the anilox roller by the pneumatic system, determining an automatically adaptive pressure dynamic to ensure the best ink distribution.

- Hi-FiX system: irreversible pneumatic locking of the printing roller with conical-shaped piston. No vibration. More quality.

- Hi-InX system: sequential separation of ink roller and printing roller to clean existing ink.

Technical Specifications