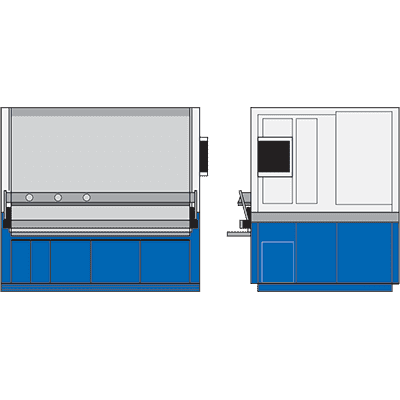

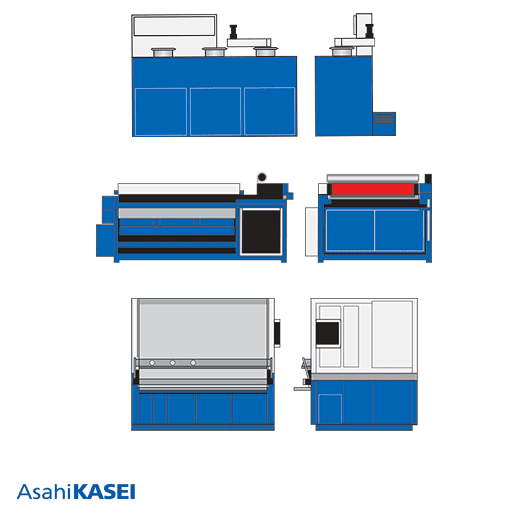

AWF 110 E-Lamination/exposure unit

Lamination/exposure operations for all functions and process sequences of the unit can be entered and controlled via a programmable controller and visualized on a color screen. APR™ sheets can be laminated to individual thicknesses of 1.7-8.0 mm in 0.01 mm increments.

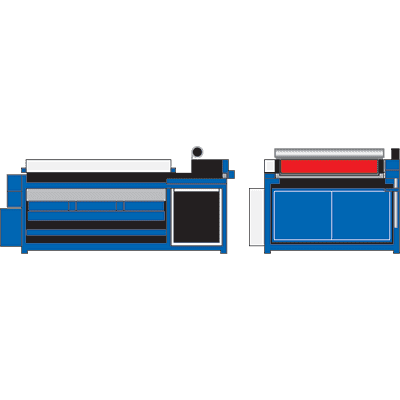

AWF110W-Processor

Lamination/exposure operations for all functions and process sequences of the unit can be entered and controlled via a programmable controller and visualized on a color screen. APR™ sheets can be laminated to individual thicknesses of 1.7-8.0 mm in 0.01 mm increments.

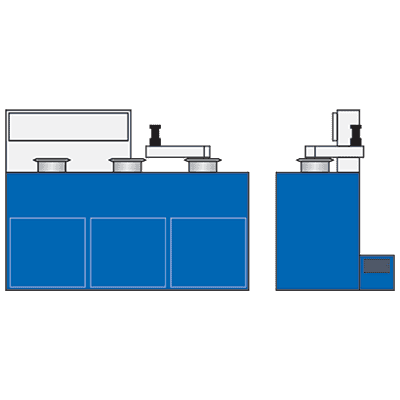

AWF110T-Photopolymer feeding tank

There are three feed tanks combined in a single unit to ensure continuous operation. Two basic photopolymer tanks with a volume of 90 liters each and a cover photopolymer tank with a volume of 18 liters combined in one unit provide sufficient capacity for continuous operation. All photopolymer tanks are equipped with level sensors and a special heater. Base photopolymer tanks are equipped with a mixer.