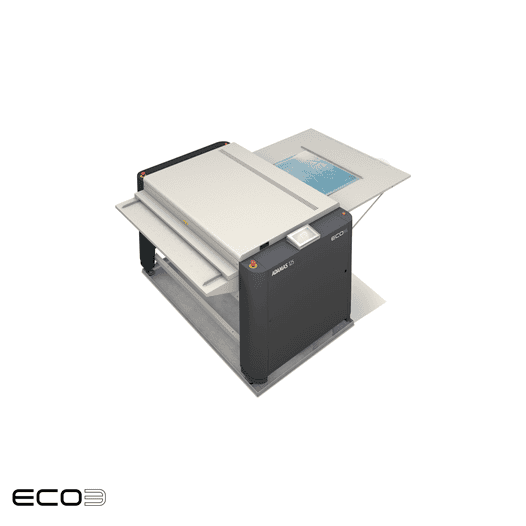

Adamas COU series consists of special, advanced and compact cleaning units that finish quickly and take ecology to the next level.

Adamas cleaning units have a bathroom life of 16,000 m² It is based on a two-gum concept consisting of a special cleaning solution and a protective finishing gum that does not require water. The new brush design ensures effective cleaning and requires only small amounts of liquid (35 ml/m²) to quickly clean the plates. As a result, CHU produces up to 80% less waste than other systems on the market.

Select your model Adamas cleaning units are available in three sizes: Adamas COU85, Adamas COU125 and Adamas COU150. They can be used alone or connected to plate exposure machine online. The latest software version has an algorithm that ensures maximum energy and waste efficiency. Once the Adamas cleaning unit is installed, you are ready: the unit is designed to process up to 60,000 m² of plates per year!

Benefits

Small ecological foot trace

These units are energy efficient, chemical free and do not require water to clean the plate.

Less waste

Long bath life, low renewal rates and complete elimination of rinse water compare to conventional thermal systems. It reduces waste by up to 80% compared to

Gradual cleaning technology

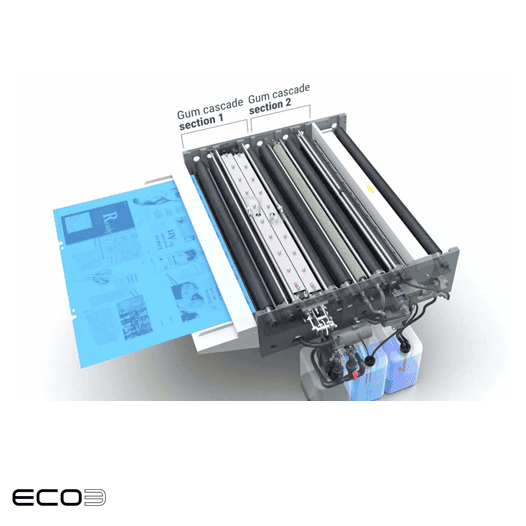

Adamas cleaning units have two gum sections. In the first, 95% of the areas not displayed are removed from the plate. A new brush design contributes to efficient cleaning with minimal chewing gum consumption. The remaining areas that are not visible in the second gum section are removed and a perfectly clean plaque is obtained.

The addition of a self-cleaning module doubles the batch life to 16,000 m². Additionally, three intermediate cleaning operations at 4,000, 8,000 and 12,000 m² are carried out as part of an automatic process that starts with a simple button press on the Adamas display and requires no further intervention from the operator.

A thin layer of gum is applied to the plate to prevent oxidation of the plate and protect it from use in the printing room. . Finally, the plate is dried with hot air so that further processing can be done immediately.